Effective canister filling at the highest level

Innovative solutions for your industry

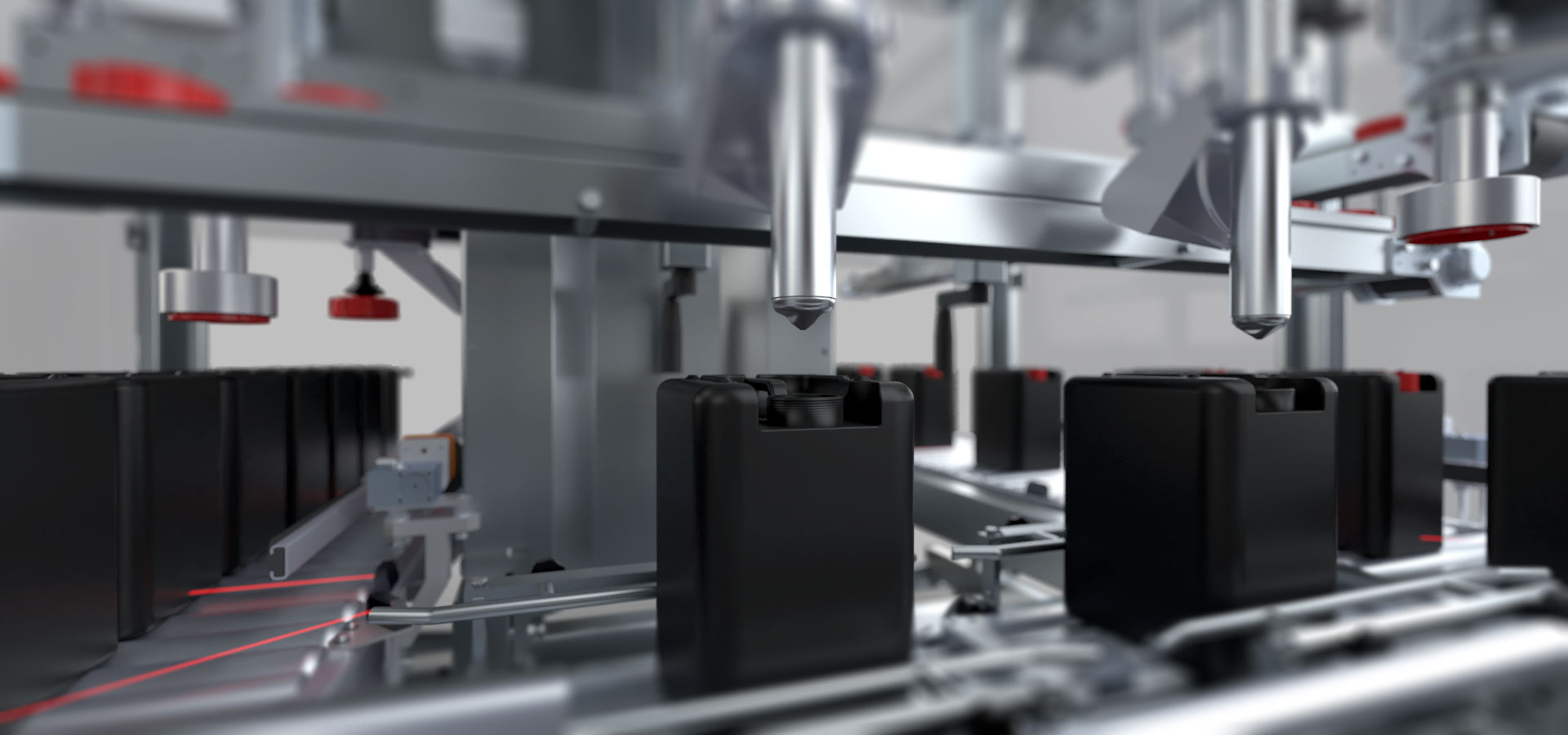

We present the perfect filling technology to meet your individual challenge. The modular concept of Feige FILLING filling equipment offers you a comprehensive product range and thus tailor-made solutions to meet all the requirements in the gravimetric filling of canisters sized from 0.5 kg to 60 kg.

Thanks to our decades of experience in dealing with innovative technology and our continuous adaptation to market needs you can rely on our guarantee that we will successfully implement your individual requirements.

Rely on us

Canisters are filled precisely and automatically by positioning the individual container at the filling valve, followed by subsequent filling with calibrated accuracy and manual closing. Our canister filling equipment effortlessly processes plastic and metal containers, while a stainless steel design is also available for the food industry.

In addition, we offer you another option in conjunction with our FEIGE palletising systems. After filling, the filled canisters can be automatically palletised. Empty containers that were palletised beforehand are successively positioned on the pallet by aligning the filling valve manually with the filling opening of the canister. Actuating the start button causes automatic taring to be carried out, followed by filling with calibrated accuracy in the well-proven coarse fill/fine fill mode. All the auxiliary tools required to ensure a precise bunging of the canisters are available to you.

Mathias Hühn

Mathias Hühn

Sales Manager

Something you can rely on

All automatic canister fillers follow a uniform operating principle. Whether single or arranged on a pallet, the canisters reach the automatic filler in an empty and clean state. There they are filled precisely and with calibrated accuracy before they leave the automatic filling machine in a clean and closed condition. Central components of the automatic canister filler are the filling valve and the weigh scale. Filling is carried out according to the well-proven coarse fill/fine fill mode. To ensure that calibration error limits are observed, it is necessary to restrict the volumetric flow at the end of the filling process.

Our core competence: the filling valve

FEIGE filling machines are characterised by their first-rate components: the filling valve and the weigh scale.

The FEIGE filling valve enables you to fill your liquid and viscous products in a precise and adaptable manner, either proportionally or in several stages. The filling operation is carried out in the well-proven coarse fill/fine fill mode, enabling an individual adjustment of the fine fill, depending on the product and your needs. To ensure that calibration error limits are observed, the volumetric flow is precisely restricted at the end of filling by a two-stage or analogue setting of the filling valve.

The filling valve is dimensioned according to filling opening, viscosity and volumetric flow in line with your requirements. For this, FEIGE uses premium materials such as stainless steel (1.4571/316Ti), Hastelloy, PVDF and coatings to ensure the reliability of the filling valve. Heatable filling valves that are equipped with overflow protections are available for different areas of application.

- Quick-action stainless steel filling valve mount

- Hygienic, self-adjustable PTFE ring seal

- Bellows made from stainless steel or PTFE

- Valve tip and opening method according to product requirements

- Precise, clean and splash-free filling method

- Easy and efficient cleaning without dismounting

- Minimum of dead spaces

As a rule, FEIGE filling valves are compensated so that the product pressure inside the valve does not influence the opening or closing behaviour. This increases the safety as pressurised filling valves cannot open spontaneously. Cleaning the FEIGE filling valves is uncomplicated and efficient as it is possible at any time without dismounting the valves. All components and seals are designed so that the filling valve is low of any dead spaces. The product hose is connected directly without intermediate flange or in a flexible manner by means of any of the flange systems available on the market to suit your requirements or standards.

The properties of your product and the container type determine the filling mode

Which filling mode do you need?

Highly viscous products, viscous substances and highly fluid foodstuff, construction materials or chemicals each necessitate a special filling method. We offer you comprehensive advice and together find a suitable solution for your requirements!

![[Translate to English:] Integra 64, Kanister, Füllen automatisch](https://www.feige.com/fileadmin/FeigeFilling/_processed_/3/5/csm_Kanister_INTEGRA_64_Fuellventil__420x271_4e2d20eb3d.jpg)

![[Translate to English:] Integra 64, Kanister, Füllen automatisch](https://www.feige.com/fileadmin/FeigeFilling/_processed_/3/5/csm_Kanister_INTEGRA_64_Fuellventil__420x271_db1cbe6775.jpg)

![[Translate to English:] Integra 64, Kanister, Füllen automatisch](https://www.feige.com/fileadmin/FeigeFilling/_processed_/3/5/csm_Kanister_INTEGRA_64_Fuellventil__420x271_088fd7cfd1.jpg)

![[Translate to English:] FEIGE Web HMI](https://www.feige.com/fileadmin/FeigeFilling/_processed_/a/9/csm_Web_HMI_420x271__a7c8427830.jpg)

![[Translate to English:] FEIGE Web HMI](https://www.feige.com/fileadmin/FeigeFilling/_processed_/a/9/csm_Web_HMI_420x271__40f6985df0.jpg)

![[Translate to English:] FEIGE Web HMI](https://www.feige.com/fileadmin/FeigeFilling/_processed_/a/9/csm_Web_HMI_420x271__5b4657353e.jpg)

![[Translate to English:] Kanisterkappenband für INTEGRA 64](https://www.feige.com/fileadmin/FeigeFilling/_processed_/f/b/csm_Kanister_INTEGRA_64_Kappenband_420x271_41fc02e904.jpg)

![[Translate to English:] Kanisterkappenband für INTEGRA 64](https://www.feige.com/fileadmin/FeigeFilling/_processed_/f/b/csm_Kanister_INTEGRA_64_Kappenband_420x271_a58ad1efae.jpg)

![[Translate to English:] Kanisterkappenband für INTEGRA 64](https://www.feige.com/fileadmin/FeigeFilling/_processed_/f/b/csm_Kanister_INTEGRA_64_Kappenband_420x271_83a80dc6dc.jpg)

![[Translate to English:] Kanister zuschrauben](https://www.feige.com/fileadmin/FeigeFilling/_processed_/c/c/csm_INTEGRA_64_zuschrauben__891de7d6d8.jpg)

![[Translate to English:] Kanister zuschrauben](https://www.feige.com/fileadmin/FeigeFilling/_processed_/c/c/csm_INTEGRA_64_zuschrauben__959de41148.jpg)

![[Translate to English:] Kanister zuschrauben](https://www.feige.com/fileadmin/FeigeFilling/_processed_/c/c/csm_INTEGRA_64_zuschrauben__a66e41017a.jpg)

![[Translate to English:] Halbautomatische Befüllung ELEMENTRA](https://www.feige.com/fileadmin/FeigeFilling/_processed_/7/7/csm_Elementra_29_final_420x271_59f1a6d737.jpg)

![[Translate to English:] Halbautomatische Befüllung ELEMENTRA](https://www.feige.com/fileadmin/FeigeFilling/_processed_/7/7/csm_Elementra_29_final_420x271_bf00965aab.jpg)

![[Translate to English:] Halbautomatische Befüllung ELEMENTRA](https://www.feige.com/fileadmin/FeigeFilling/_processed_/7/7/csm_Elementra_29_final_420x271_d65fd131b1.jpg)

![[Translate to English:] Halbautomatische Befüllung ELEMENTRA](https://www.feige.com/fileadmin/FeigeFilling/_processed_/7/7/csm_Elementra_29_final_420x271_78a260da88.jpg)

![[Translate to English:] ATEX-Ausführung](https://www.feige.com/fileadmin/FeigeFilling/_processed_/c/f/csm_Ex-Zeichen_schwarz-02-01_548c82f752.jpg)

![[Translate to English:] ATEX-Ausführung](https://www.feige.com/fileadmin/FeigeFilling/_processed_/c/f/csm_Ex-Zeichen_schwarz-02-01_b673ca61fd.jpg)

![[Translate to English:] ATEX-Ausführung](https://www.feige.com/fileadmin/FeigeFilling/_processed_/c/f/csm_Ex-Zeichen_schwarz-02-01_e7ff619251.jpg)

![[Translate to English:] Kernkompetenz von Feige: Füllventile](https://www.feige.com/fileadmin/FeigeFilling/_processed_/3/4/csm_Ersatzteile_Ventile_420_271_1cfce6a82d.jpg)

![[Translate to English:] Kernkompetenz von Feige: Füllventile](https://www.feige.com/fileadmin/FeigeFilling/_processed_/3/4/csm_Ersatzteile_Ventile_420_271_45fad34669.jpg)

![[Translate to English:] Kernkompetenz von Feige: Füllventile](https://www.feige.com/fileadmin/FeigeFilling/01_Graphic/1366_Content/Ersatzteile_Ventile_420_271.jpg)

![[Translate to English:] Abfüllart: Unterspiegel](https://www.feige.com/fileadmin/FeigeFilling/_processed_/0/3/csm_Unterspiege_Feige_bf4c44abd9.png)

![[Translate to English:] Abfüllart: Unterspiegel](https://www.feige.com/fileadmin/FeigeFilling/_processed_/0/3/csm_Unterspiege_Feige_507b7795ba.png)

![[Translate to English:] Abfüllart: Unterspiegel](https://www.feige.com/fileadmin/FeigeFilling/_processed_/0/3/csm_Unterspiege_Feige_721073f7b5.png)

![[Translate to English:] Abfüllart: Überspiegel](https://www.feige.com/fileadmin/FeigeFilling/_processed_/f/0/csm_UEberspiegel_feige_c1d8e57b7f.png)

![[Translate to English:] Abfüllart: Überspiegel](https://www.feige.com/fileadmin/FeigeFilling/_processed_/f/0/csm_UEberspiegel_feige_bc05e112ac.png)

![[Translate to English:] Abfüllart: Überspiegel](https://www.feige.com/fileadmin/FeigeFilling/_processed_/f/0/csm_UEberspiegel_feige_4a4e663280.png)

![[Translate to English:] Abfüllart: Unterspundloch](https://www.feige.com/fileadmin/FeigeFilling/_processed_/3/1/csm_Unterspundloch__Feige_2541ea09d2.png)

![[Translate to English:] Abfüllart: Unterspundloch](https://www.feige.com/fileadmin/FeigeFilling/_processed_/3/1/csm_Unterspundloch__Feige_cb12466f24.png)

![[Translate to English:] Abfüllart: Unterspundloch](https://www.feige.com/fileadmin/FeigeFilling/_processed_/3/1/csm_Unterspundloch__Feige_4a477a25fa.png)