Pallet and IBC filling

No matter from which product line you choose your filling machine: Feige makes no difference in quality referring to filling valves, filling accuracy and filling speed. The same components are used in all lines.

Pallet filling station ELEMENTRA® 16

With the pallet filling station ELEMENTRA® 16 additional requirements can be fulfilled:

- Driven conveyor system with up to 3 drive units

- Flip-open pit scale

- Stainless steel design

- Advanced protection against highly corrosive products

- Standard stainless steel load cells

- Additional overflow signal

- Nitrogen purging

- Administration of 255 filling parameter sets

- Fully wired on delivery

We recommend calling in our Service Center for connecting the drive units, for commissioning and verification.

The pallet filling station ELEMENTRA® 16 is largely pre-configured.

Pallet filler ELEMENTRA® 17

fulfils the same requirements as type 16.

For positioning the filling unit, however, the boom arm is not pivoted but shifted to the side.

Please opt for this type if the area to the right and to the left of the pallet is not accessible to the operator.

Pivoting pallet filling equipment ELEMENTRA® 26

With the pivoting pallet filling equipment ELEMENTRA® 26 further and more complex requirements can be fulfilled:

- Extensive conveyor systems with accessories

- Differences in container heights of more than 800mm

- Bungholes of pallet schemes may point outward

- Level controlled upward movement

- Interface to process control system

- Further adaptations according to your requirements

We recommend calling in our Service Center for installation on site, commissioning and verification.

IBC filling equipment ELEMENTRA® 28

With the IBC filling equipment ELEMENTRA® 28 further and more complex requirements can be fulfilled:

- Extensive conveyor systems with accessories

- Differences in IBC heights of more than 800mm

- Level controlled upward movement

- Interface to process control system

- Further adaptations according to your requirements

We recommend calling in our Service Center for installation on site, commissioning and verification.

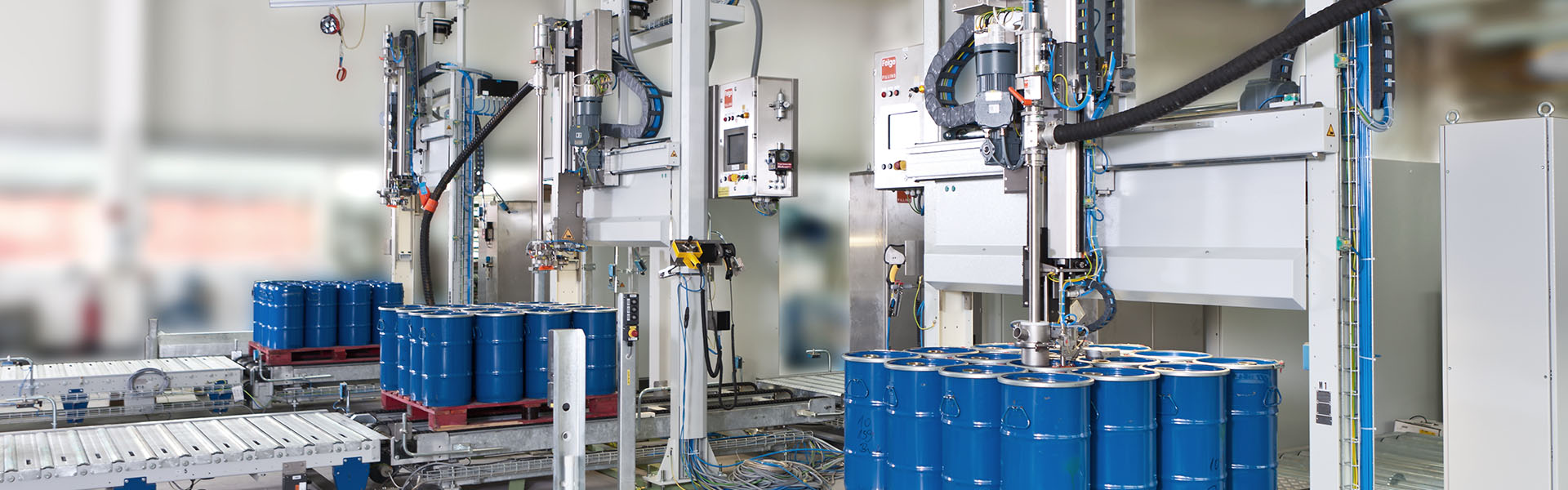

Pallet filling robot ELEMENTRA® 71

Comprehensive portal pallet filling robot for filling IBCs, drums and containers with camera system for bunghole detection.

Pallet filling robot ELEMENTRA® 72

Sturdy portal pallet filler for filling IBCs, drums and containers, also designed for multi-layer filling. Bunghole approach by means of joystick.